The Future of EMI Shielding Is Lightweight, Flexible, and Ready for Flight

By Ralph Schafer, Technical Director D&AE

Modern military aircraft represent some of the most complex electronic environments ever engineered. These platforms integrate advanced avionics, radar systems, data links, and communication networks that must function seamlessly in hostile, high-frequency environments. In these mission-critical contexts, electromagnetic interference (EMI) poses a silent but serious threat that can degrade signal integrity, cause crosstalk between systems, or even lead to mission failure.

The combination of increasing data rates, higher frequencies, and more complex electromagnetic environments demands shielding solutions that can deliver superior performance while contributing to overall system weight reduction. This challenge has driven innovation toward advanced materials that maintain electrical effectiveness while dramatically reducing mass.

Understanding EMI in Aerospace Applications

Electromagnetic interference occurs when unwanted electromagnetic energy disrupts electrical signals. This energy can be radiated through space or conducted along wires and ground planes. In military aircraft, EMI sources include internal subsystems like power supplies and switching electronics, as well as external threats such as jammers, lightning strikes, and radar systems.

“The electromagnetic environment in a modern fighter aircraft is absolutely unforgiving,” explains Ralph Schafer, Technical Director D&AE. “We’re dealing with radiated power levels and frequency densities that would have been unimaginable even a decade ago. The margin for error in EMI protection has essentially disappeared.”

Effective shielding uses conductive or magnetic materials to block, reflect, or absorb EMI energy. Three core loss mechanisms exist in transmission lines: reflected energy at impedance mismatches, absorbed energy lost to heat in conductors and dielectrics, and radiated energy leakage into the environment. The challenge in effective shielding lies in addressing radiated energy leakage.

For military-grade systems, shielding effectiveness targets typically exceed 100 dB for standard signal lines and 110 dB or more for RF and microwave systems. These stringent requirements demand shielding solutions that provide consistent performance across broad frequency ranges while maintaining mechanical reliability under extreme conditions.

Traditional Shielding Approaches and Their Limitations

Conventional EMI shielding has long relied on materials like tinned copper braids, silver-plated copper constructions, and foil-braid combinations. While these materials offer proven electrical performance, they present significant challenges for next-generation aerospace applications.

Copper-based shields are inherently heavy, contributing substantial mass to cable harnesses—a critical concern when every gram affects payload capacity, range, and fuel efficiency. These traditional metal braids exhibit mechanical memory, retaining shape when bent and potentially stressing underlying conductors. This rigidity limits design flexibility and can reduce system lifespan in dynamic environments.

Furthermore, copper shields are prone to corrosion and fatigue over time, particularly in the harsh environmental conditions common to military operations. Salt spray, chemical exposure, extreme temperature cycling, and mechanical vibration can all compromise shield integrity and performance.

Traditional copper braids were once sufficient for simpler avionics and lower data rates. However, modern platforms now demand shielding capable of handling gigabit-per-second data streams while enduring 20-year service lives in hostile environments. Unfortunately, copper falls short of simultaneously fulfilling both of these demands.

The SWaP Imperative in Modern Aerospace

Size, Weight, and Power (SWaP) optimization has become a defining constraint in aerospace, space, defense, and unmanned aerial vehicle systems. Engineers face relentless pressure to make every gram, millimeter, and watt count toward mission success. While shielding might seem like a background concern, it plays a critical role in enabling advanced system capabilities.

Modern military aircraft systems require minimum shielding coverage exceeding 90% optical coverage, with overbraids grounded at both ends and all intra-harness signals enclosed within continuous shield paths. Meeting these requirements with traditional materials often results in cable harnesses that are heavier, bulkier, and less flexible than optimal.

Depending on the platform, the cable harness can constitute a substantial portion of an aircraft’s weight. This weight directly impacts the aircraft’s payload capacity or range, making weight reduction critical to mission effectiveness.

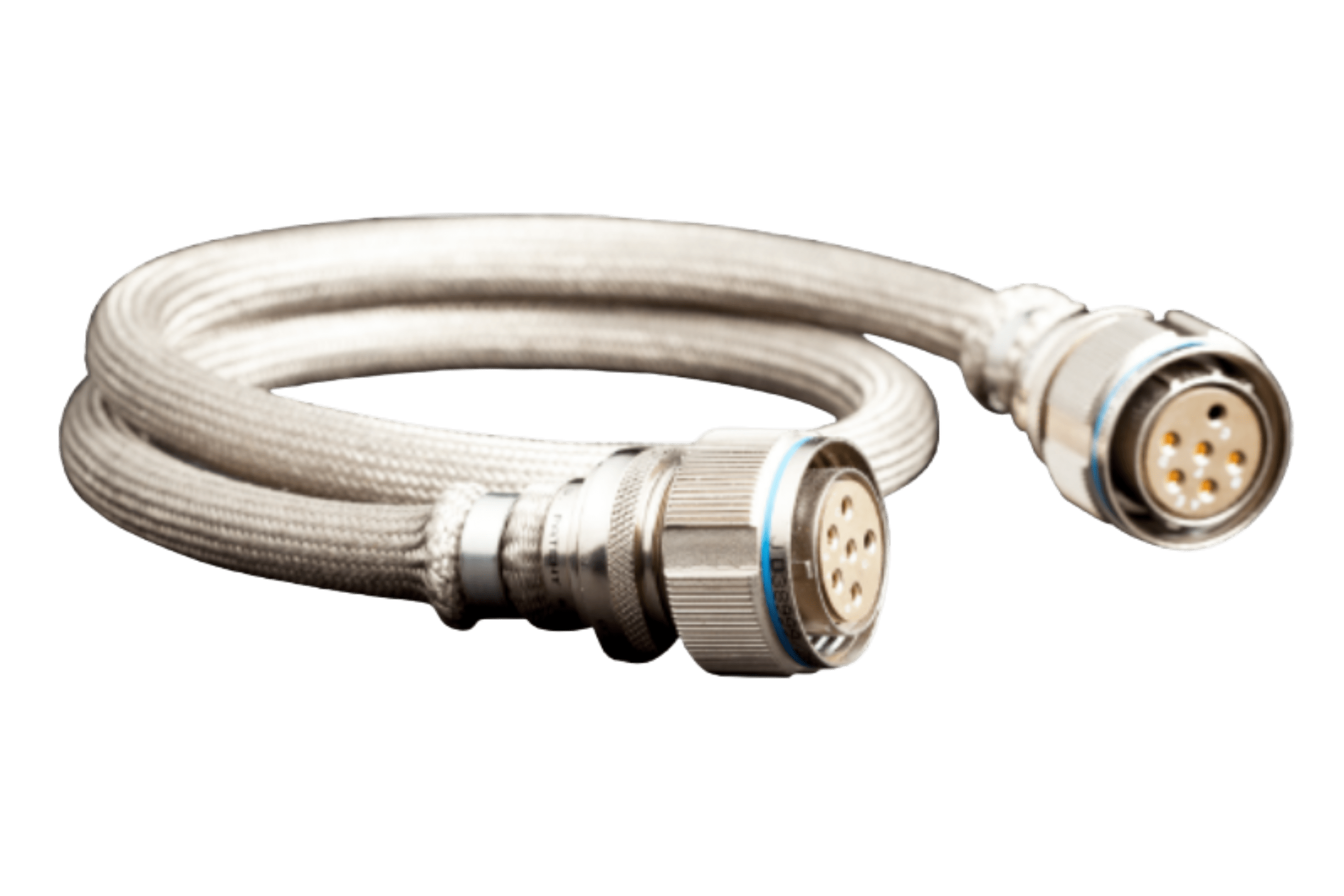

Advanced Materials: The ARACON® Solution

ARACON fiber, manufactured by Micro-Coax, represents a breakthrough in EMI shielding technology, addressing the fundamental limitations of traditional copper-based approaches. Built from Kevlar®-based fibers clad in conductive metals such as silver or nickel, ARACON fiber provides equivalent electrical performance to copper shielding while achieving up to 80% weight reduction.

ARACON fiber, manufactured by Micro-Coax, represents a breakthrough in EMI shielding technology, addressing the fundamental limitations of traditional copper-based approaches. Built from Kevlar®-based fibers clad in conductive metals such as silver or nickel, ARACON fiber provides equivalent electrical performance to copper shielding while achieving up to 80% weight reduction.

The material’s core strength comes from DuPont™ Kevlar®, renowned for its exceptional strength-to-weight ratio. When plated with conductive metals, the resulting textile-like braid acts as a lightweight electromagnetic shield that also resists corrosion, fatigue, and mechanical stress. With shielding coverage exceeding 90%, this material effectively blocks EMI over a broad frequency spectrum, safeguarding signal integrity in the most demanding applications.

Unlike copper, ARACON fiber’s soft, pliable nature allows it to bend, wrap, and conform without mechanical memory. This flexibility eliminates the shape retention, also known as mechanical memory, that can stress delicate cables. The material’s fabric-like properties also simplify installation, requiring no special tools and enabling cleaner, more compact cable layouts.

Performance Advantages in Critical Applications

ARACON fiber’s unique properties translate into measurable advantages across multiple performance dimensions. The material’s tightly woven, ultra-fine filaments create a high-surface-area braid that delivers exceptional RF shielding, particularly at high frequencies where traditional braids begin to degrade.

Weight reduction represents perhaps the most significant advantage. In aircraft and spacecraft, where weight directly impacts cost and capability, ARACON fiber enables real-world cable harness weight reductions of 26% or more. These weight savings can translate into additional payload capacity, extended range, or improved fuel efficiency—delivering mission-critical advantages.

The material’s unmatched flexibility proves crucial in applications involving complex routing through airframes, robotic joints, or vehicle interiors. Where copper retains shape when bent and potentially stresses underlying wires, this material conforms naturally without mechanical memory, reducing wear and improving system lifespan in dynamic environments.

“Installation and maintenance are often overlooked aspects of cable harness design,” observes Ralph Schafer, Technical Director D&AE. “With traditional copper braids, technicians need specialized tools and have to be extremely careful about bend radius. ARACON fiber installs like fabric—you can cut it with scissors and route it through tight spaces without worrying about damaging the underlying conductors.”

For composite aircraft structures that lack inherent conductivity, ARACON fiber can be custom blended with copper to meet RTCA DO-160 lightning protection standards. This capability ensures electrical fault protection and lightning strike survivability without excessive mass penalties.

Environmental Durability and Qualification

ARACON fiber demonstrates exceptional performance across the harsh environmental conditions typical of military aerospace applications. The material operates reliably across temperature ranges from -110°C to +150°C and resists degradation from salt spray, chemical exposure, fuel, oil, and intense thermal cycling.

Comprehensive qualification testing confirms the material’s compliance with the most demanding industry standards, including IEC 61000-4-21 for RF shielding effectiveness, RTCA DO-160 for lightning susceptibility, ASTM B-117 and G-85 for corrosion resistance, and MIL-STD-810 for environmental durability. The material also meets FAA CFR 14 Part 25 requirements for flammability, smoke, and toxicity, along with ASTM E-595 low outgassing standards for space applications.

This extensive qualification heritage provides confidence for engineers designing systems that must perform reliably over decades of service life in challenging operational environments.

Real-World Applications Across Defense Platforms

In commercial and military aviation, the material shields flight control wiring, avionics systems, in-flight entertainment networks, and grounding systems. ARACON fiber’s FAA-compliant fire resistance and vibration durability make it suitable for both new aircraft platforms and weight-saving retrofit applications.

Space applications leverage the fiber’s low mass characteristics for shielding solar arrays, telemetry harnesses, and navigation controls. The material’s low outgassing properties and wide thermal range have been proven in both low Earth orbit (LEO) and geostationary missions, with over 30 years of spaceflight heritage.

Military ground vehicles, rotorcraft, and command, control, communications, computers, intelligence, surveillance, and reconnaissance (C4ISR) systems benefit from ARACON fiber’s flexible, corrosion-resistant shielding that survives high-G maneuvers and multi-strike lightning events. The material’s durability proves particularly valuable in weapon interfaces and tactical communication systems.

Configuration Options and Custom Engineering

Braided sleeves provide comprehensive protection for cable bundles, while conductive yarn enables embedding or weaving into custom configurations. Hybrid braids combining ARACON fiber with copper allow engineers to tune EMI performance and DC resistance characteristics for specific applications.

Plating options include silver for enhanced solderability and nickel for superior corrosion and wear resistance. Diameter options range from less than 1/16 inch to 2 inches, with custom put-ups, strength specifications, and braid constructions available to meet unique program requirements.

This flexibility enables engineers to optimize shielding performance for specific applications while maintaining the material’s core advantages in weight, flexibility, and environmental durability.

The Future of Aerospace EMI Shielding

As military aircraft advance toward higher data rates, increased autonomy, and enhanced stealth capabilities, EMI shielding must evolve to meet escalating performance demands.

For decades, engineers have been forced to choose between electrical performance and weight, between flexibility and durability, between cost and capability. ARACON fiber eliminates these trade-offs entirely. By delivering superior EMI protection in a lightweight, flexible package that withstands the harshest environments, ARACON fiber enables engineers to design without compromise.

In an era where every gram matters and mission success depends on optimized performance, ARACON fiber proves that advanced materials can redefine what’s possible in aerospace EMI shielding—delivering everything engineers need in one unified solution.

Kevlar® is a registered trademark of DuPont. DuPont™ is a trademark of DuPont.

ARACON ® is a registered trademark of Amphenol CIT.

Subscribe Now!

Interested in receiving email newsletters and other updates from Micro-Coax? Subscribe to receive our quarterly newsletter, product updates and more.